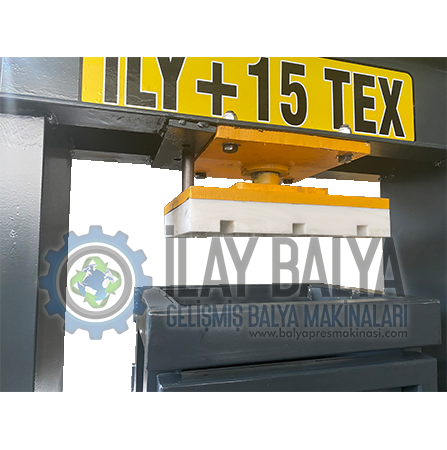

VERTICAL TEXTILE BALER PRESS MACHINE ILY 15 TEX

Vertical Textile Baler Press Machine ILY 15 TEX

What is the Vertical Textile Baler Press Machine ILY 15 TEX?

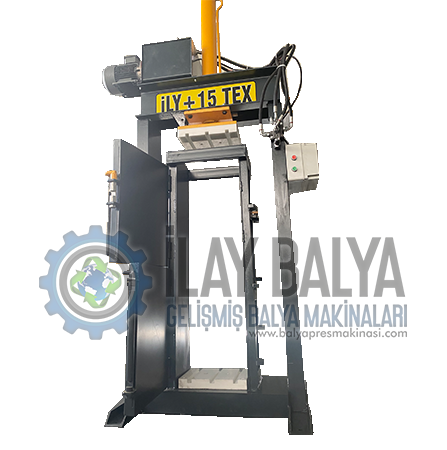

The Vertical Textile Baler Press Machine ILY 15 TEX is a machine designed to compress textile waste materials such as towels, fabric scraps, cotton, and wool into neat and transportable balers. Manufactured with high-quality parts, this machine offers great convenience in the industry thanks to its robust construction and efficient working principle. Additionally, the conveyor system and various control options provide flexibility for operators.

Advantages of the Vertical Textile Baler Press Machine ILY 15 TEX

Durable and Strong Structure

Made with quality materials, offering long-lasting performance.

High Efficiency

Compresses textile waste quickly and systematically, facilitating waste management.

Suitable for Various Materials

Successfully presses different materials such as towels, fabric scraps, cotton, and wool.

Conveyor System

Speeds up the material feeding process, saving time.

MANUAL SYSTEM / PLC SYSTEM Option

Provides ease of use with both manual or automatic control.

Various Baler Weights

Balers can be produced in the range of 20-100 kg.

How Does the Vertical Textile Baler Press Machine ILY 15 TEX Work?

The machine begins the compression process by feeding textile waste or other materials into the press chamber. The operator determines the machine’s working mode through either the MANUAL SYSTEM or the PLC SYSTEM control. Then, the materials are fed into the machine in an organized manner using the conveyor system, and they are compressed with the preset pressure. Finally, the compressed material is formed into a baler and is ready for transportation.

Conveyor System and Ease of Use

Thanks to the conveyor system, the material feeding process is automated, saving labor. This accelerates the pressing process of textile waste and ensures more efficient production.

Applications of the Vertical Textile Baler Press Machine ILY 15 TEX

- Textile factories

- Waste recycling plants

- Cotton and wool processing plants

- Fabric production centers

With its wide range of applications, the machine serves many industries, optimizing work processes.

What to Consider When Purchasing the Vertical Textile Baler Press Machine ILY 15 TEX

Some points to consider when buying the machine include:

Material Compatibility

Whether the materials to be used are compatible with the machine.

Conveyor System and Control Mechanisms

Whether the conveyor system and control mechanisms are suitable for the needs.

Production Capacity and Baler Weight

Whether the production capacity and baler weight range meet expectations.

Spare Parts and Technical Support

The availability of spare parts and technical support services.

Conclusion

The Vertical Textile Baler Press Machine ILY 15 TEX is one of the most efficient solutions for compressing textile waste and other soft materials. With its durable structure, ease of use, and various system options, it offers great advantages in the industrial sector. The conveyor system accelerates the process, ensuring high efficiency. If you are looking for a high-quality and durable baler press machine, this model will be an ideal choice for you.

Make your textile waste neat and compact with the Vertical Textile Baler Press Machine ILY 15 TEX! Manufactured with high-quality parts, this powerful machine compresses materials like towels, fabric scraps, cotton, and wool to create transportable balers. The conveyor system ensures fast and efficient operation, helping you save on labor and time. With the MANUAL SYSTEM and PLC SYSTEM options, it offers both manual and automatic usage flexibility. Its durable construction ensures long-term use and optimizes work processes in the industrial sector. It is the perfect solution for more organized, efficient, and cost-effective production!

| BALER DIMENSIONS | BALE DIMENSIONS |

| Height: 2.800m | Height: 0.800 m |

| Width: 1.500 m | Width: 0.500 m |

| Depth: 1.000 m | Depth: 0.500 m |

| Weight: 500 kg | Weight: 20-100 kg (Depends on the Material Used) |

| Transport Height: 2.50 m | Cycle Time: 24 sec |

| Power Supply: 380 – 400 Volt 3 phase | SUPPLY PORT DIMENSIONS |

| Engine: 3 kW 16 Amp | Height: 1,400 m |

| Press Power: Maximum 15 Tons | Width: 0.500 m |

| Noise Level: 72 Decibels | Depth: 0.400 m |