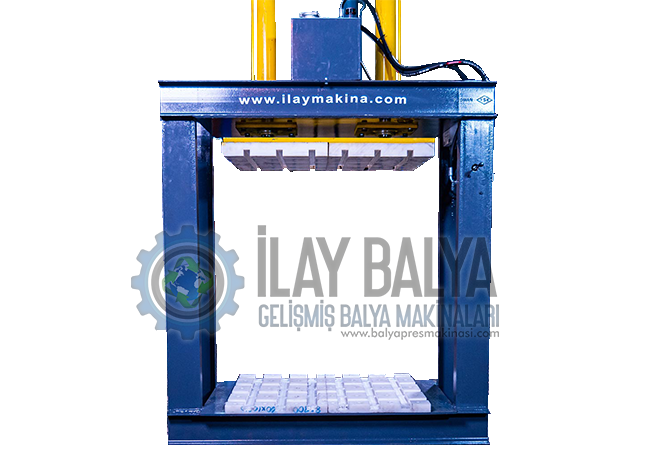

OPEN HOPPER VERTICAL TEXTILE PRESS MACHINE ILY 25 TEX

Vertical Textile Baler Press Machine ILY 25 TEX

What is the Vertical Textile Baler Press Machine ILY 25 TEX?

The Vertical Textile Baler Press Machine ILY 25 TEX is a powerful machine specially designed to enhance efficiency and simplify waste management in the textile industry. It compresses materials such as towels, fabric scrap, cotton, and wool into compact and portable bales. Manufactured with high-quality components, this machine offers long-lasting performance while helping you optimize your work processes. With its conveyor system and various control options, it provides operators with flexibility and ease of use.

Advantages of the Vertical Textile Baler Press Machine ILY 25 TEX

Robust and Durable Construction

Made with superior quality materials, it is resistant to intensive usage conditions.

High Efficiency

Compresses textile waste quickly and effectively, making the production process more organized.

Wide Material Compatibility

It processes various materials, including towels, cotton, wool, and fabric scrap.

Advanced Conveyor System

Speeds up material feeding, saving labor and time.

MANUAL HANDLE SYSTEM and PLC SYSTEM Option

Offers both manual and automatic operation options depending on user needs.

Various Bale Weights

Bales can be produced with weights ranging from 30 to 150 kg.

How Does the Vertical Textile Baler Press Machine ILY 25 TEX Work?

This machine compresses textile waste by placing it into a special compression chamber and applying high pressure. The operator controls the machine through the manual HANDLE SYSTEM or the automatic PLC SYSTEM. The conveyor system continuously and regularly feeds the materials into the chamber, increasing processing speed. Once the preset compression pressure is reached, the machine forms the bale and prepares it for transport.

Conveyor System and Ease of Use

The conveyor system optimizes the workflow by ensuring continuous material feeding without requiring manual intervention. This system reduces labor costs, accelerates the production process, and saves time for operators.

Applications of the Vertical Textile Baler Press Machine ILY 25 TEX

Textile Factories

Organizes waste during production, facilitating recycling.

Waste Recycling Facilities

Compresses textile waste for better storage and transportation.

Cotton and Wool Processing Plants

Allows controlled processing of raw materials and consistent bale production.

Fabric Production Centers

Compresses excess fabric waste in a regular manner, saving space.

This machine is an excellent solution for meeting various needs within the textile industry due to its wide range of applications.

What to Consider When Purchasing the Vertical Textile Baler Press Machine ILY 25 TEX?

The right machine selection can directly impact your business’s production process. Consider the following factors during the purchasing process:

Material Compatibility

Ensure the machine is compatible with the materials you plan to compress.

Conveyor System and Automation

Does your need align with a manual or automated system?

Production Capacity

Check the bale weight ranges that match your business’s daily production requirements.

Technical Support and Spare Parts

Gather information about after-sales technical support and availability of spare parts.

Conclusion

The Vertical Textile Baler Press Machine ILY 25 TEX is an ideal solution for organizing textile waste and improving recycling processes. With its sturdy structure, wide range of applications, and high compression capacity, it provides significant advantages to businesses. The conveyor system accelerates the process, while the automatic or manual control options offer flexibility to operators. If you’re looking for a high-quality, durable textile baler press machine, this model will be an excellent choice for you.

| BALER DIMENSIONS | BALE WEIGHT AND CYCLE TIME |

| Height: 2.800m | Weight: 30-150 kg (Depends on the Material Used) |

| Width: 1.850 m | Cycle Time: 30 sec |

| Depth: 1,500 m | |

| Weight: 1500 kg | |

| Transport Height: 2.80 m | |

| Power Supply: 380 – 400 Volt 3 phase | |

| Engine: 4 kW 32 Amp | |

| Press Power: Maximum 25 Tons | |

| Noise Level: 72 Decibels |