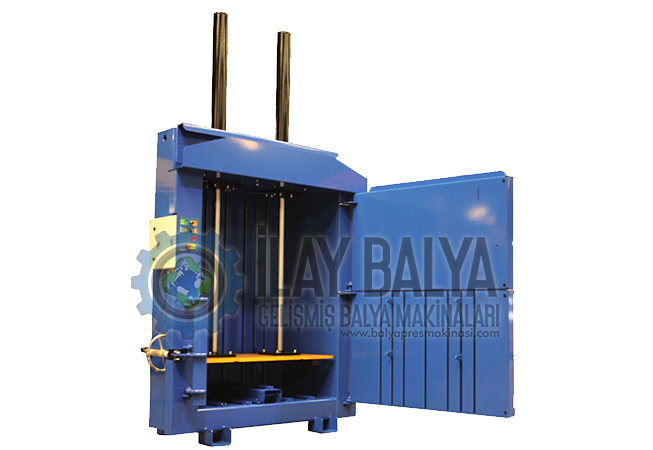

BALE PRESS MACHINE ILY550

Vertical Baler Press Machine ILY550: The Ideal Solution for High Performance and Efficiency

Innovation in Waste Management with Vertical Baler Press Machine ILY550

In today’s industrial sector, the efficient processing of recyclable materials is of great importance in providing eco-friendly and cost-effective solutions. This is precisely where the Vertical Baler Press Machine ILY550 comes into play. This machine, with its high-performance structure, enables the compression of large amounts of waste materials and offers significant space savings for businesses. As an ideal solution for effective industrial waste management, it is specially designed in response to demands from various sectors.

High Capacity and Advanced Technology Features

Features of the Vertical Baler Press Machine ILY550

The Vertical Baler Press Machine ILY550 is specifically designed for processing large amounts of recyclable materials. In addition to its practical use, it stands out with its durable structure. Thanks to its vertical design, materials are easily compressed without occupying much space, making space utilization in businesses more efficient.

The machine’s bale weight is 550 kg, ensuring that compressed materials take up less space after the pressing process. This feature is particularly advantageous for recycling facilities and businesses with large storage areas.

Compression of Recyclable Products

The Vertical Baler Press Machine ILY550 can compress a wide variety of materials, including cardboard, paper, plastic, nylon, wool, cotton, fabric, textile waste, rubber, sacks, garbage waste, packaging materials, fiber, bottles, bags, tin cans, and PET bottles. The compression of these materials not only saves space but also accelerates the recycling process. As a result, businesses reduce recycling costs and minimize environmental impacts.

Vertical Compression System and Safety Features

The machine’s vertical compression system allows for more efficient compression of materials. This system ensures high efficiency while enhancing operational safety. The five-channel tying system secures each bale more effectively, preventing deformation during the pressing process and ensuring safety during transportation.

Fully Automatic Bale Ejector System

The machine is equipped with a fully automatic bale ejector system. This feature makes bale removal extremely easy. Thanks to the automatic ejector, bales can be quickly and practically relocated. This saves time and improves labor efficiency, especially in large-scale recycling facilities.

Optional Features and Additional Equipment

110-Volt Power Supply and Electronic Control System

The machine’s ability to operate with a 110-volt power supply is a significant advantage for businesses with different electrical infrastructures. Additionally, with the electronic control system, the pressing process can be easily monitored and controlled, allowing operators to manage all machine functions comfortably.

Galvanized Coating and Durability

The galvanized coating protects the machine’s outer surface and ensures long-lasting durability. Thanks to this coating, the machine can be used safely for many years, even under challenging working conditions.

Tin Can Crusher Attachment

Another optional feature of the machine is the tin can crusher attachment, which allows the compression of 5-20 liter tin and food cans. This attachment lifts the can, enabling the press head to apply full compression force. It can also be used with plastic containers, steel cans, and fiber drums. This ensures the efficient processing of various types of waste.

Optimize Space Utilization with Vertical Baler Press Machine ILY550

The Vertical Baler Press Machine ILY550 is a perfect solution for businesses handling large amounts of waste materials. This machine is both eco-friendly and cost-effective. By compressing waste, less space is occupied, resulting in significant savings in storage and transportation costs. Additionally, the efficient processing of recyclable materials is a major advantage for environmentally conscious businesses.

Conclusion: High Efficiency and Safety with Vertical Baler Press Machine ILY550

The Vertical Baler Press Machine ILY550 ensures efficient management of industrial waste with its high efficiency and safety features. The compression of recyclable materials helps businesses increase profitability while reducing their environmental impact. With a fully automatic bale ejector, a secure tying system, optional features, and a durable structure, this machine is an ideal solution for all types of businesses.

Not only is it indispensable in the recycling sector, but it is also suitable for various industrial processes. By enhancing labor efficiency and reducing operational costs, the Vertical Baler Press Machine ILY550 is an essential machine for businesses looking for both eco-friendly and economical solutions.

| BALER FEATURES | BALE FEATURES |

| Height: 3.217 m | Height: 1.200 m |

| Width: 2.115m | Width: 1.500 m |

| Depth: 1.200 m | Depth: 0.700 m |

| Weight: 1650 kg | Weight: 550 kg (Depends on the material used) |

| Transport Height: 2.5 m | Cycle Time: 40 sec |

| Power Supply: 380 – 400 Volt 3 phase | SUPPLY SPECIFICATIONS |

| Engine: 11 kW 32 Amp | Height: 0.880m |

| Press Power: Maximum 50 Ton | Depth: 0.700 m |

| Noise Level: 72 decibels | Width: 1,500 m |